|

|||

|

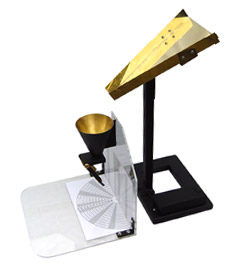

Powder Characterisation All companies manufacturing or simply using powders as feedstocks need to know quickly if the flowability of the powder is changing from day to day or week to week, in order to ensure that the processing equipment shall continue to behave according to its design specification However, the flow behaviour of powders can sometimes change due to slight changes in process conditions, such as the relative humidity or temperature of the ambient air, or more importantly, due to changes in the powder itself such as particle size distribution; mean particle size; particle shape and roughness; and even a change in chemical formulation that alters the electrostatic properties of the material. There are many pieces of equipment available to measure important powder properties such as particle size, particle size distribution, and shear strength. However, most of these instruments have a high capital cost and require skilled technicians to get reliable results. Moreover, because the handling properties of powders are seldom related linearly to variations in the parameters listed above, the results of measuring such properties may be insufficient to predict flow properties. Usually it is necessary to know only whether today’s batches have better or worse flowability than the powders produced yesterday. A piece of equipment that is light but robust, easy to use, only requires small powder samples and relatively inexpensive, is available from Powder Research Ltd.

The Powder Research Ltd AOR device for measuring angle of repose quickly and reliably was developed by Professor Geldart & his research students working closely with a large UK chemical company and the Mark4 version is now available and can be used on a range of powders, even those that are very fine and cohesive. For further information and price, contact Professor Derek Geldart at prfgeldart@aol.com

|

||

| |

|||